Hybrid fabrics Industry

Evolving automotive sector to impact hybrid fabrics market forecast over 2019-2025

Global hybrid fabrics market share is witnessing a positive growth momentum owing to increased consumer proclivity towards light-weight and environment-friendly automotive components. The automotive manufacturing sector is growing rapidly towards making cars more intelligent with a viable option of fiber optic technology which is becoming a preferred choice for a variety of automotive application. With its distinct features, fibers have become a natural choice for various functional and aesthetic components in all types of vehicles, outlining hybrid fabrics industry trends.

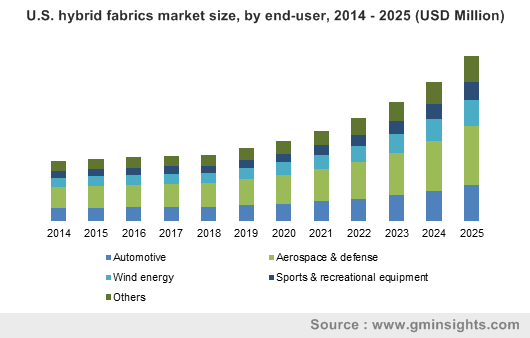

U.S. hybrid fabrics market size, by end-user, 2014 – 2025 (USD Million)

Automobile companies are constantly pushing themselves to manufacture the lightest cars possible to augment the speed and efficiency. As industries demand materials with a higher strength to weight ratios, corrosion resistance, and efficient workability, the carbon fiber is presently the most discussed lightweight material because of its high potential for weight reduction in automobiles, but the high cost involved in producing its will leading manufacturers to opt for carbon-glass hybrids, which also provide favorable properties.

U.S. sales of hybrid electric vehicles represented around 36% of more than 11 million hybrids sold globally through April 2016. With the government’s focus on renewable energy, the automobile companies are emphasizing more on manufacturing hybrid and electric vehicles along with ensuring growing awareness among customers. As these vehicles require reliable, robust and lightweight components to help improve overall efficiency, increased sales of hybrids and full-electric cars will considerably bolster hybrid fabrics market outlook in the forthcoming years.

Technological developments and emerging policy actions could further enhance the value proposition for prospective electric vehicle buyers. Leading metropolitan EV markets tend to have public charging infrastructure, consumer subventions, and other incentives that would propel the need for electric vehicle manufacturing, further stimulating the expansion of hybrid fabrics industry over the projected timeframe. Reportedly, the highest selling hybrid electric vehicle in the U.S. was Toyota Prius, which had sold approximately 1,643,000 units since year 2000 through April 2016.

Get a Sample Copy of this Report:@ https://www.gminsights.com/request-sample/detail/3324

Electric vehicles offer the potential to save significant costs and time. Lightweight fabrics have become the material of choice owing to their functionality and flexibility and have opened up several new spots for lightweight automotive manufacturing. They also allow for lower maintenance and repair costs, since carbon/glass hybrid fabric could be inexpensive as compared to carbon alone. The combination will also witness substantial demand for other applications and it was reported that the carbon/glass segment contributed nearly 30% of global hybrid fabrics market size in 2018.

With the rapid upsurge in the automobile technology, the hybrid fabrics are created from a broad variety of different fibers including combinations of carbon fiber and aramid fiber. Aramid fibers are used extensively, from passenger cars and light trucks to professional racing cars and also known for their high tensile strength. Apart from their resistance to abrasion and piercing, they also comprise high resistance to organic solvents and fire. The cost component of using aramid alone has advocated the need for hybrid materials that also helps to improve performance, safety, and durability of a broad range of automotive components.

Lately, various industry players like Solvay, Gurit, Hexcel Corporation, and BGF Industries Inc. are capitalizing on their R&D finesse to develop pioneering and innovative products, which can provide them an edge over the competition and also fetch lucrative profits. They are also looking to expand their presence through mergers and acquisitions. For instance, in 2016 the parent company of BGF Industries, Porcher Industries had announced the acquisition of Cordtech International which is specialized in the treatment and processing of industrial fibres for the car market.

Expanding production capabilities to meet the burgeoning demand for auto components is poised to boost hybrid fabrics industry trends over the coming years. The development of groundbreaking production technologies will undeniably create lucrative growth prospects for various hybrid fabric manufacturers. Reports suggest that owing to a wide application scope, which includes aerospace, energy, sports and defense sectors, global hybrid fabrics market is anticipated to surpass a valuation of USD 400 million by 2025.

Author Name : Deeksha Pant